DDP, the largest 3D amorphous structure in the world

Designed by Zaha Hadid, the first female architect to win the Pritzker Prize, the DDP is the world's largest three-dimensional atypical building.

Zaha Hadid's DDP design included a new landscape of Dongdaemun, which adds new future values and visions on the historical, cultural, social, and economic foundation of Dongdaemun.

Zaha Hadid created a seamless space for nature and artifacts with a unique architectural language consisting of curves, curves, slopes, and slopes, focusing on the dynamics of Dongdaemun, which changes from early dawn to night. Based on this concept, DDP added a new landscape to the symbolism of Dongdaemun.

| Location | Euljiro 281 DDP, Jung-gu, Seoul (previously Dongdaemun Stadium) |

|---|---|

| Scale | Gross area: 86,574㎡ (3 stories underground, 4 stories above ground, with maximum height of 29m) |

| Project Duration |

2009.04.28 ~ 2014.03.21

|

| Space |

5 facilities, 15 spaces

|

| Design | Zaha Hadid Architects + Samoo Architects and Engineers Construction: Samsung C&&T Corporation |

| Construction | Samsung C&&T Corporation |

| Management | Seoul Design Foundation |

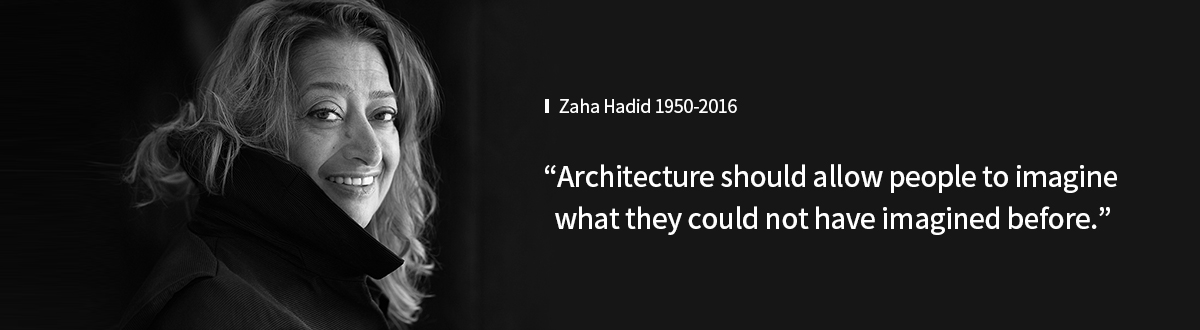

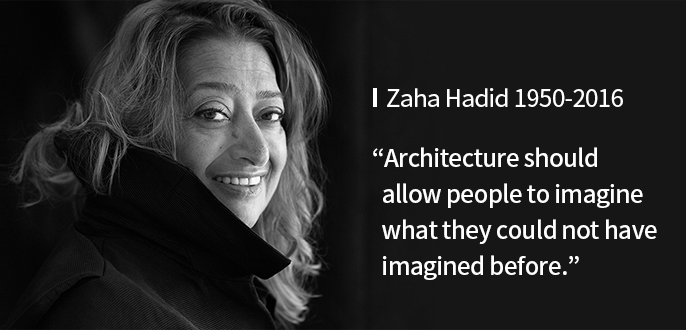

Zaha Hadid has achieved global recognition for her organic designs, and is known as an innovative architect who constantly pushes the limits of architecture and the concepts of city and design. In 2004, she became the first woman to win the Prizker Architecture Prize, known as the “Nobel Prize” of architecture. Some of her projects include the Architecture Foundation in London, the London Aquatics Centre for the 2012 Summer Olympics, the Sheikh Zayed Bridge and the Guggenheim Performing Arts Center in Abu Dhabi, the Business Bay Towers in Dubai, and Pierres Vives in Montpellier, France.

The construction of the amorphous DDP structure would have been virtually impossible using existing two-dimensional design plans. However, Seoul Metropolitan Government, the Seoul Design Foundation, and Samsung C&T used technology developed in Korea, a three-dimensional design approach called BIM (Building Information Modeling), to complete the new landmark structure. BIM has recently been applied to the construction of buildings, but only partly, such as on exterior walls of buildings. The DDP was the first case in Korea which employed the BIM approach throughout the whole process, including excavation, construction, interior finishing, MEP (mechanical electrical plumbing), and landscaping. BIM allowed the external panels to be built and installed flawlessly.

The design of DDP employs mega-trusses and a space frame, minimizing the use of columns and creating a massive interior space with seemingly endless curves. DDP utilizes a space frame to span large curved areas and mega-trusses, which are usually used for larger structures such as bridges, to support the cantilevered space frame. Using such advanced construction technology and techniques, DDP could hold expansive interior spaces without additional support structures.

The DDP is finished with 45,133 aluminum panels in varying sizes and patterns. None of them are the same. This sets DDP apart from other architectural structures.

Since the external panels differ in size, curvature, and pattern, the existing production and installation methods could not guarantee the design, quality, and timely completion of the project. Also, there were no similar structures anywhere in the world to benchmark. Determined to successfully complete the external panel installation within budget and on time, Samsung C&T reviewed all known metal forming technologies used in shipbuilding as well as airplane and automobile manufacturing to develop the equipment necessary to form and cut the multiple-curved panels, the first equipment of its kind in the world.

DDP features exposed amorphous concrete surfaces of various shapes inside and outside of the building, creating a unique atmosphere. This type of concrete is designed to be used as an exposed surface without applying additional finishing material and requires careful construction of the framework and concrete casting. The exposed concrete finish of DDP was even more difficult due to its curved and amorphous structure. So, Samsung C&T used the BIM method to create a cross-section of the building every 300 mm and built the framework using a rib plywood framework method. Also, for the amorphous interior framework, the company used external panel forming equipment with stainless steel and aluminum, to realize the smooth and amorphous exposed concrete surface.

The curved interior of DDP is finished with high-quality, eco-friendly, fire-resistant plaster boards, GRG (glass fiber-reinforced gypsum) boards, cotton sound absorption panels, and imitation marble. Before finalizing the three-dimensional design, Samsung C&T created several life-sized visual mockups of the amorphous interior, using the cutting-edge BIM method, in order to ensure quality construction.